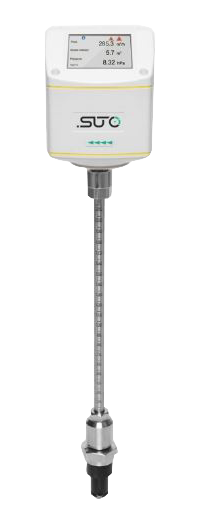

SUTO-iTEC dewpoint sensor / dew point monitor S 215

The SUTO-iTEC dew point sensor S 215 provides reliable and long term stable dew point monitoring in industrial applications. With these new models dew point measurement in refrigerant dryers becomes affordable and can replace traditional temperature measurement which often couldn’t tell the real dew point. S 215 outputs the measurement value through the loop powered 4-20 mA signal

Application

Dew point measurement is used in:

Compressed air dryers and before sensitive equipment

- Plastic injection process resin drying

- Blow molding process

- Medical gases in hospitals

- Compressed air purity in food and pharmaceutical industry

- In all industrial processes requiring high purity of clean and dry air (CDA)

Product features

- Affordable dew point sensor for mid range applications such as refrigerant dryer monitoring

- Long term stability

- IP65 casing provides robust protection in rough industrial environment

- Very fast response time ensures safe and reliable indication whenever dew points are out of valid ranges

- Can be installed directly into dryers through G 1/2″ thread

- High accuracy of ± 2 ºC dew point

Technical data

| Measuring range Dew point Relative humidity Temperature |

-20…50 °C 0…99.9 % -30…70 °C |

| Accuracy | ±2 °C dew point |

| Pressure range | -0.1 … 5.0 MPa |

| Power supply | 10 … 30 VDC |

| Ambient conditions | -20 … 50 ºC |

| Response time t90 | 0…-20 ºC: 30 sec -20…0 ºC: 10 sec |

| Output signal | 4…20 mA, 2-wire |

| Connection | M12, 5 pole |

| Casing | Zinc alloy |

| Classification | IP65 |

| Process connection | G 1/2” thread (ISO 228/1) UNF 5/8″ thread (on request) |

| Transport temperature | -30 … +70 ºC |

Stationary use

Stationary use