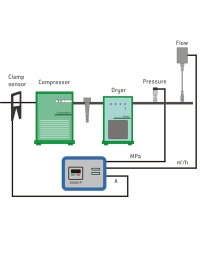

Current clamp sensor

SUTO-iTEC Miniflex 1000 current clamp sensor is an AC RMS current sensor composed of a flexible active part (Rogowski coil model) connected to a compact digital converter, capable of measuring the current carried on a power conductor up to a value of 1000 Aac.

The digital converter supplies an output of 4-20 mA DC in linear proportion to the measured current.

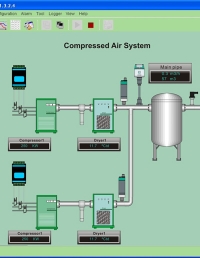

Application

- Current sensing at compressors for load / Unload analyzes

- Current sensing for power / Energy measurement

- Evaluation of machine operation hours

Product features

- Easy installation

- Wide measuring range

- Accurate current sensing

- 4-20 mA output signal

Technical data

| Measuring range | 10 …1000 A AC |

| Fundamental frequency |

40 … 70 Hz |

| Output signal | 4 … 20 mA DC – 0 A AC measured = 4 mA DC output – 1000 A AC measured = 20 mA DC output |

| Maximum output | 21,6 mA DC |

| Load impedance | ≤ 300 Ω |

| Accuracy | 0.5% of reading + 0.2% of range |

| Power supply | 10 VDC to 32 VDC |

| Current consumption |

≤ 30 mA |

| Max. Clamp capacity |

100 mm ± 2 mm |

| Maximum temperature of clamped cable |

≤ +80 °C |

| Protection rating | IP67 |

| Service voltage | ≤ 1000 CAT III, 600 V CAT IV |